0

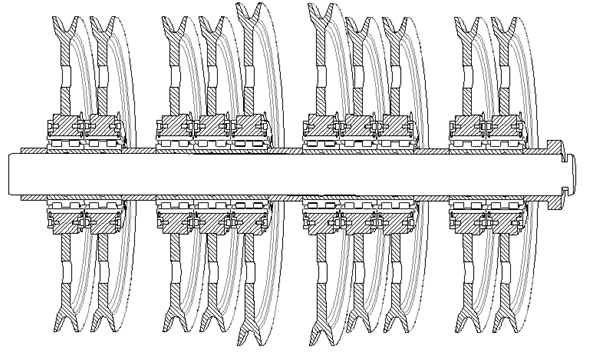

01)crane Sheaves block structure

2) Container Crane Sheave Block description

1. Sheave large range of size available: Φ800 mm~Φ3000mm

2. Sheave rim Forging Material : 45(S45C); Q345B Q345D,Q345E( used for -40℃) ,35CrMo and so on or according clients request for sheaves

3. Sheave groove :

a. Groove profiles : according client request and manufacture by CNC .

b. groove heat treatment by intermediate frequency quenching , hardness Min. HB350-370 and deep around ≥2.5mm . (different material can getting different hardness )

c. Groove MT test after heat treatment

4. Sheave welding process according WPQR (WPS) AWD1.1 welding line

|  |  |

|  |  |

If you are interested in our products and want to know more details, please leave a message here, and we will reply to you as soon as possible.

Tel: 0086-519-88100328

WhatsApp: +86-0086-519-88100328

Email: sales@baoxincz.com

No 1788, Huacheng Road, Jintan District, Changzhou City, Jiangsu Province, China

Changzhou Baoxin Metallurgy Equipment Manufacturing Co., Ltd. is a high-tech enterprise registered in Changzhou City of Jiangsu Province, which is mainly engaged in the design and manufacture of spare parts for metallurgy equipment, hoisting machinery, oil drilling rigs, and heavy decelerator boxes.