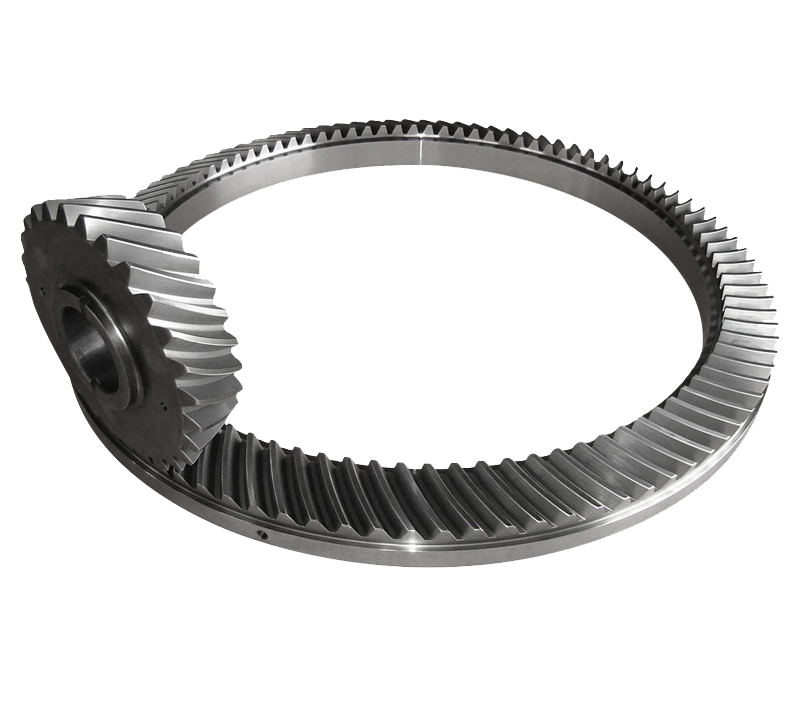

Comparison of helical teeth and bevel teeth

May 10, 2017|

May 10, 2017| View:611

View:611Comparison of helical teeth and bevel teeth

Spiral bevel gears have their teeth formed along spiral lines. They are somewhat analogous to cylindrical type helical gears in that the teeth are angled; however, with spiral gears, the teeth are also curved.

The advantage of the spiral tooth over the straight tooth is that they engage more gradually. The contact between the teeth starts at one end of the gear and then spreads across the whole tooth. This results in a less abrupt transfer of force when a new pair of teeth come into play. With straight bevel gears, the abrupt tooth engagement causes noise, especially at high speeds, and impact stress on the teeth which makes them unable to take heavy loads at high speeds without breaking. For these reasons, straight bevel gears are generally limited to use at linear speeds less than 1000 feet/min; or, for small gears, under 1000 r.p.m.

Therefore, the spiral tooth life is very high, and the use of better results in the cone crusher gradually replaced the original bevel gear.

View More(Total0)Comment lists