How Crane Sheaves Contribute to Smooth and Efficient Lifting Operations

Aug 25, 2023|

Aug 25, 2023| View:1792

View:1792In the world of heavy lifting and construction, crane sheaves play a pivotal role in ensuring the smooth and efficient operation of cranes. These seemingly simple yet critical components contribute to the proper functioning of the lifting mechanism, enabling cranes to handle heavy loads with precision and safety. In this article, we will explore what crane sheaves are, how they work, and their significance in various lifting applications.

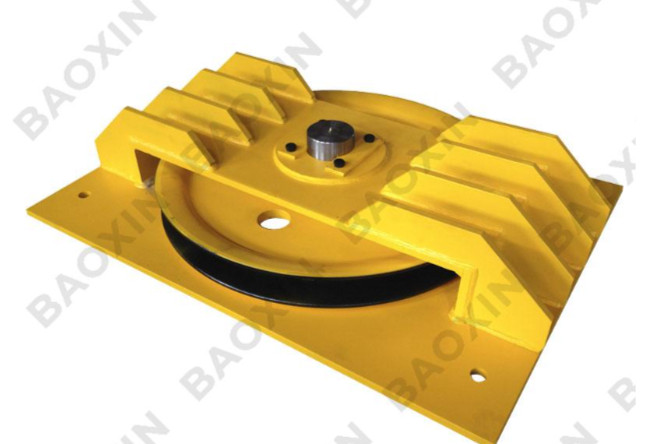

What Are Crane Sheaves?

Crane sheaves, also known as pulleys, are wheel-like devices with a groove or channel that runs around the circumference. They are usually mounted on the crane's hook block or trolley and are an integral part of the crane's hoisting system. The rope or wire rope used for lifting passes through the groove in the sheave, creating a system of mechanical advantage that makes lifting heavy loads easier.

How Do Crane Sheaves Work?

The functionality of crane sheaves can be broken down into the following key steps:

Load Attachment: The crane hook block is connected to the load to be lifted. The load is usually attached to the hook block using various rigging methods.

Rope Thread: The lifting rope, often a wire rope, is threaded through the groove of the crane sheave. This rope is wound around the sheave's groove to create multiple layers of contact, enhancing friction and grip.

Lifting Process: As the crane's hoist motor engages and the rope is wound around the sheave, the load is lifted vertically. The sheave's rotation and groove ensure that the load's weight is evenly distributed across the rope's multiple layers.

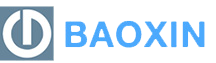

Mechanical Advantage: The design of the sheave and the arrangement of the rope create a mechanical advantage that allows the crane to lift loads that are much heavier than the lifting capacity of the hoist motor alone.

Significance of Crane Sheaves in Lifting Operations:

Load Distribution: Crane sheaves distribute the load's weight evenly across the rope, preventing uneven wear and ensuring safe lifting operations.

Reduced Wear: Properly designed and maintained sheaves reduce wear on the lifting rope, prolonging its lifespan and lowering maintenance costs.

Controlled Movement: Sheaves enable precise control of load movement by adjusting the speed and direction of the rope winding around the sheave.

Enhanced Efficiency: The mechanical advantage provided by crane sheaves allows cranes to lift heavier loads with less strain on the hoist motor, increasing efficiency and reducing energy consumption.

Applications of Crane Sheaves:

Construction Sites: Crane sheaves are essential in construction projects for lifting materials, equipment, and structures to various heights.

Manufacturing Facilities: Industries rely on cranes and sheaves for moving heavy machinery and components along assembly lines.

Shipyards and Ports: Sheaves are integral to cranes used for loading and unloading cargo from ships and containers.

Mining Operations: In mining, crane sheaves help lift and transport massive quantities of materials and ores.

Key to Smooth and Efficient Lifting

crane sheaves are a fundamental element of lifting operations across industries. Their design and function contribute to the safe and precise movement of heavy loads, enabling cranes to perform their tasks effectively. Whether in construction, manufacturing, or transportation, crane sheaves play a critical role in maintaining the integrity and efficiency of lifting operations, underscoring their significance in modern industrial processes.

View More(Total0)Comment lists