Optimizing Efficiency: How Spiral Bevel Gears Improve Power Transmission

Jul 20, 2023|

Jul 20, 2023| View:1298

View:1298

Spiral bevel gears are essential components in various mechanical systems to transfer power efficiently and smoothly. In this article, we will delve into the unique characteristics of spiral bevel gears that contribute to optimizing efficiency in power transmission. Whether designing new machinery or upgrading existing systems, understanding the advantages of spiral bevel gears can greatly enhance performance and reliability.

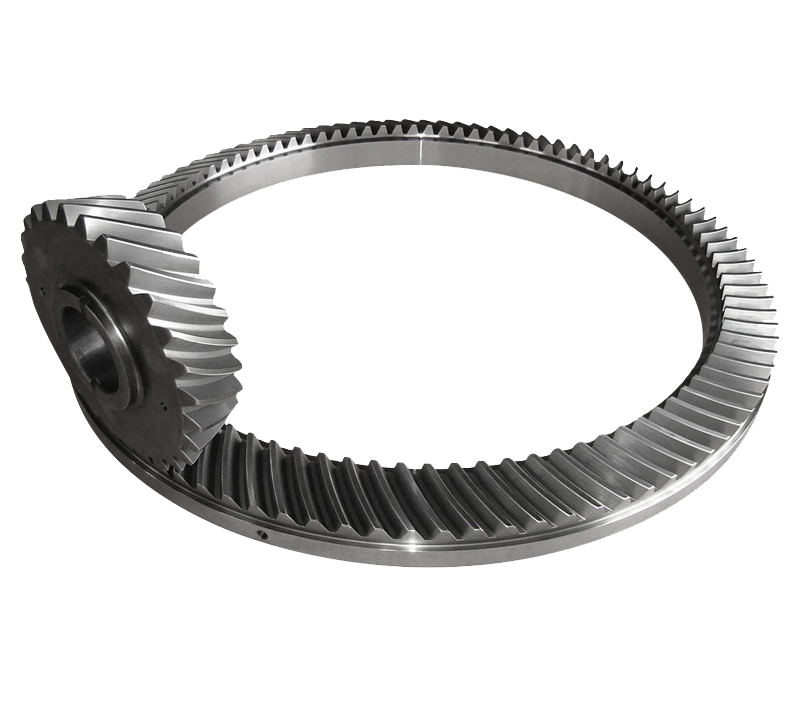

The Design and Geometry of Spiral Bevel Gears

Spiral bevel gears are precision-engineered with a curved tooth profile, allowing for gradual engagement. This design ensures smoother and quieter operation compared to straight bevel gears. The spiral arrangement also enables a larger contact area between gear teeth, enhancing load-carrying capacity and minimizing stress concentrations.

Reducing Friction and Heat Generation

One key advantage of spiral bevel gears is their ability to distribute load and force more evenly across the gear teeth. As a result, the meshing action generates less friction and heat, leading to reduced wear and longer gear life. Lower friction translates into higher overall efficiency, as less power is lost to internal losses.

Enhancing Power Transmission Efficiency

Spiral bevel gears are known for their high efficiency in transferring power between intersecting shafts. Their precisely cut teeth ensure a constant and consistent meshing motion, minimizing energy losses during transmission. This characteristic is particularly crucial in applications where power needs to be transmitted over long distances or under heavy loads.

Precision Manufacturing and Quality Control

To maximize efficiency, manufacturing spiral bevel gears requires a high degree of precision. Advanced machining technologies and stringent quality control measures ensure that each gear meets exacting standards. Proper gear alignment and tooth contact are essential for optimizing efficiency and reducing the risk of premature failure.

Versatility in Application

Spiral bevel gears find applications in various industries, including automotive, aerospace, marine, and heavy machinery. Their ability to handle varying speeds, loads, and torque levels makes them suitable for various power transmission scenarios. From automobile steering systems to helicopter rotor assemblies, spiral bevel gears are critical in modern engineering.

In conclusion, the efficiency of power transmission in mechanical systems greatly depends on the choice of gear technology. With their unique design and precise manufacturing, spiral bevel gears offer distinct advantages that optimize power transfer efficiency and system performance.

View More(Total0)Comment lists