BAOXIN Heat Treatments

May 04, 2017|

May 04, 2017| View:646

View:646Baoxin Heat Treatments

Heat treatment is a process that controls the heating and cooling of a material, performed to obtain the required structural properties of metal materials. Heating methods include normalizing, annealing quenching, tempering, and surface hardening.

NOTE 1. For nitriding, it is necessary that the material contains one or more alloy elements, such as Al, Cr, Mo. V.

(1) Normalizing

Normalizing is a heat treatment applied to the microstructure of the small crystals of steel to unify the overall structure. This treatment is performed to relieve internal stress or to resolve inconsistent fiber structures occurred by the forming processing such as rolling.

(2) Annealing

Annealing is a heat treatment applied to soften steel, adjust the crystalline structure, relieve internal stress, and modify it for cold-working and cutting performance. There are several types of annealing in accordance with the application, such as Full Annealing, Softening, Stress Relieving, Straightening Annealing, and Intermediate Annealing.

Full Annealing

Annealing relieves internal stress without changing the structure.

Straightening Annealing

Annealing to fix deformation occurred in steel or other materials. The treatment is performed by applying load.

Intermediate Annealing

Annealing is applied in the process of cold-working, applied to soften the work-hardened material, so to make the next process easier.

(3) Quenching

Quenching is a treatment on steel, applying rapid cooling after heating at high temperatures. There are several types of quenching in accordance with cooling conditions; water quenching, oil quenching, and vacuum quenching. It is essential to apply tempering after quenching.

(4) Tempering

Tempering is heat treatment, applying cooling at a proper speed. After performing quench hardening, the material is heated again, then, tempering is applied. Tempering must be performed after quenching. Quenching is applied to adjust hardness, add toughness, and relieve internal stress. There are two types of tempering, one is high-temperature tempering, and the other is low-temperature tempering. Applying the tempering at a higher temperature, more toughness is obtained, although the hardness decreases.

For thermal refining, high-temperature tempering is performed.

For induction hardening or carburizing, the required tempering performed after surface-hardening treatment is, low-temperature tempering.

(5) Thermal Refining

Thermal Refining is a heat treatment applied to adjust the hardness/strength/toughness of steel. This treatment involves quenching and high-temperature tempering, in combination. After thermal refining is performed, the hardness is adjusted by these treatments to increase the metal's machinable properties.

(6) Carburizing

Carburizing is a heat treatment performed especially to harden the surface in which carbon is present and penetrates the surface. The surface of low-carbon steel is carburized (Carbon penetration) and in a state of high carbon, where quenching is required. Low-temperature tempering is applied after quenching to adjust the hardness.

Not only the surface, but the inner material structure is also somewhat hardened by some level of carburizing, however, it is not as hard as the surface.

If a masking agent is applied on a part of the surface, carbon penetration is prevented and the hardness is not changed. The target hardness on the surface and the hardened depth are:

– Quench Hardenss 55 – 63 HRC (reference value)

– Effective Hardened Depth 0.3 – 1.2 mm (reference value)

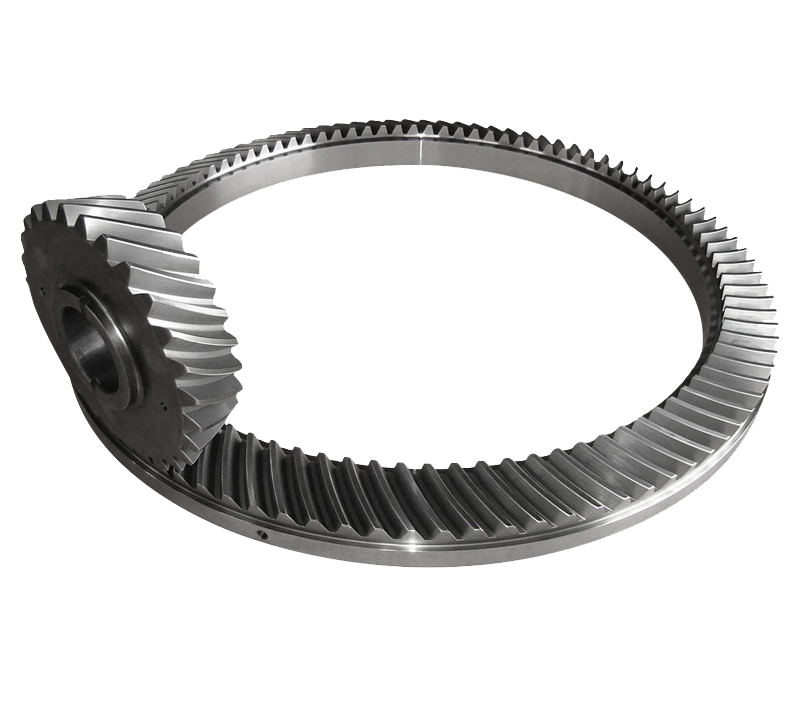

Gears are deformed by carburizing, and the precision is decreased. To improve precision, gear grinding is necessary.

(7) Induction Hardening

Induction Hardening is a heat treatment performed to harden the surface by induction-heating of the steel, composed of 0.3% carbon. For gear products, induction hardening is effective for hardening tooth areas including the tooth surface and the tip, however, the root may not be hardened in some cases.

Generally, the precision of gears declines from deformation caused by induction hardening.

(8) Flame Hardening

Flame Hardening is a surface-hardening treatment performed by flame heating. This treatment is usually performed on the surface for partial hardening of iron and steel.

(9) Nitriding

Nitriding is a heat treatment performed to harden the surface by introducing nitrogen into the surface of the steel. If the steel alloy includes aluminum, chrome, and molybdenum, it improves nitriding and the hardness can be obtained.

(10) Total Quenching

Heat treatment by heating the entire steel material to the core, and then cooling rapidly afterward, where not only the surface is hardened, the core part is also hardened.

View More(Total0)Comment lists