Induction hardening

May 08, 2017|

May 08, 2017| View:518

View:518Induction hardening--Heat treatment

Corrosionpedia explains Induction Hardening

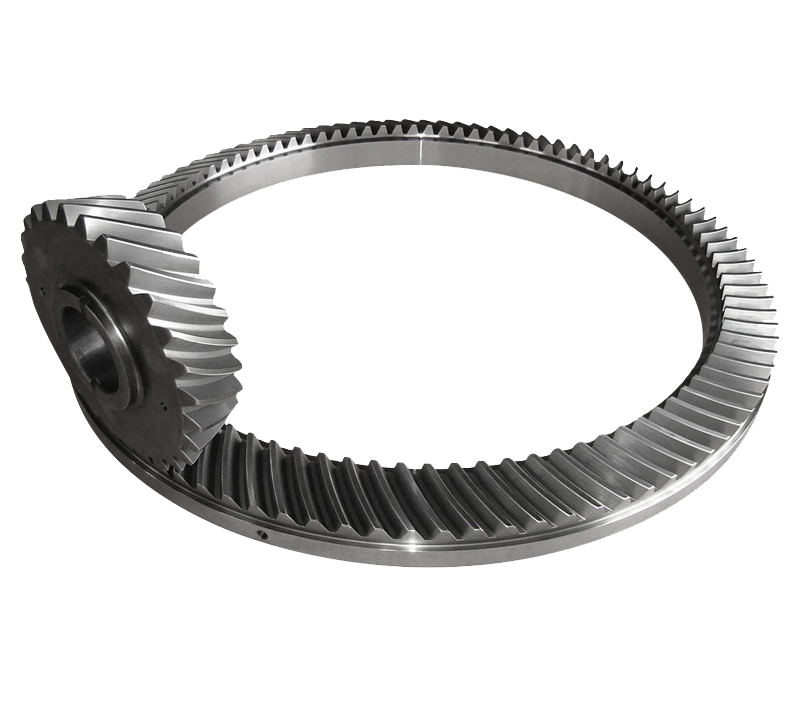

Changzhou Baoxin Induction hardening is used for surface hardening of steel and other alloy components through heating and then quenching. By quenching this heated layer in water, oil, or a polymer, the surface layer is altered to form a martensitic structure which is harder than the base metal.

The parts to be heat treated are placed inside a copper coil and then heated above their transformation temperature by applying an alternating current at a specific frequency and power level to the coil. The components are heated by means of an alternating magnetic field to a temperature at or above the transformation range followed by immediate quenching.

Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole. It is favored for components that are subjected to heavy loading, torsional loading, and impact forces.

Properties of induction hardening include:

Very quick and efficient

Allows for localized hardening

The core of the material remains the same

High control over the quality

Less distortion than other heating methods like carburizing and flame hardening

Increases durability and resistance to wear

View More(Total0)Comment lists