Crane Sheave Revolutionizes Lifting Operations with Innovative Design

Oct 08, 2023|

Oct 08, 2023| View:1676

View:1676In the world of heavy lifting and construction, a groundbreaking innovation has emerged that promises to transform lifting operations. The crane sheave, a vital component of lifting equipment, has undergone a remarkable redesign, incorporating cutting-edge technology and engineering. This revolutionary development is set to redefine efficiency and safety in the construction industry.

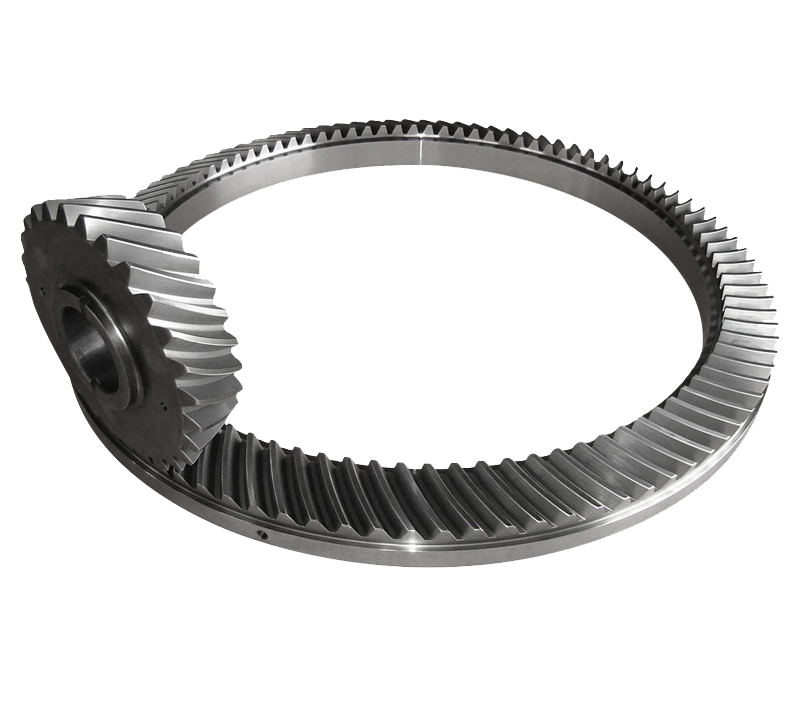

What is the Crane Sheave?

The crane sheave is a critical component within the lifting mechanism of cranes. It is a grooved wheel mounted on an axle that supports and guides the lifting rope or cable. Traditionally, crane sheaves were designed with a fixed groove diameter. However, the latest advancement in crane sheave technology introduces an adjustable groove diameter feature.

Adjustable Groove Diameter:

The innovative design of the crane sheave allows for the adjustment of the groove diameter according to the specific lifting requirements. This feature provides unprecedented flexibility and efficiency in lifting operations. By modifying the groove diameter, operators can optimize the distribution of load on the lifting rope, thereby enhancing load stability and reducing stress on the equipment.

Enhanced Safety and Durability:

The adjustable groove diameter feature of the crane sheave significantly improves safety in lifting operations. It allows for better control over the lifting process, minimizing the risk of sudden load shifts or rope slippage. Furthermore, the design incorporates advanced materials and precision engineering, ensuring exceptional durability and reliability even under the most demanding working conditions.

Increased Efficiency and Productivity:

With the ability to adjust the groove diameter, the crane sheave enables precise control over lifting operations. This level of control enhances efficiency and productivity by minimizing downtime and reducing the need for manual adjustments. Operators can quickly adapt the crane to different load sizes and optimize lifting performance, ultimately saving time and resources.

Versatility and Adaptability:

The new generation of crane sheaves offers versatility and adaptability to various lifting applications. The adjustable groove diameter feature allows for seamless transitions between different types of loads, eliminating the need for multiple sheaves or complicated setup changes. This versatility streamlines operations, making the crane more adaptable to different projects and reducing equipment costs.

Industry Impact:

The introduction of the adjustable groove diameter crane sheave marks a significant milestone in the construction and lifting industry. Its innovative design revolutionizes lifting operations, providing enhanced safety, efficiency, and versatility. With this game-changing technology, construction companies can expect increased productivity, reduced downtime, and improved project timelines.

Conclusion:

The crane sheave's adjustable groove diameter feature represents a paradigm shift in lifting operations. Its innovative design ensures optimal load distribution, enhanced safety, and improved efficiency. As this groundbreaking technology continues to gain traction in the construction industry, it holds the promise of transforming how lifting operations are conducted, paving the way for safer, more productive, and technologically advanced construction sites.

View More(Total0)Comment lists