0

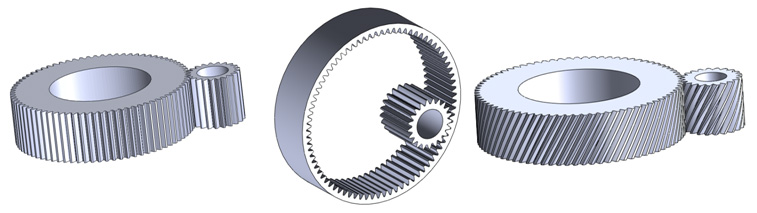

01) Spur gear structure

2) Spur gear description

a. gear teeth form: spur gear

b. Spur gear range of size available : Dia. 200mm -8000mm

c. Gear material: ASTM, BS, DIN, NF, JIS, ISO standard , high strength alloy steel , such as :42CrMo ;17CrNiMo6;20CrMoTi ;40CrNiMo; 40CrNi2Mo, and so on or according customer request for gear .

d. Helical spur gear heat treatment : according material and application gear choose different heat treatment such as : quenching and tempering ( hardness HB300-330) ; teeth surface carburizing (hardness HRC≥55,depth 1.5-3 mm) ; teeth surface ion nitriding (hardness HRC≥55,depth 0.7-1.5 mm) ; surface induction hardness (hardness HRC≥55,depth 1-2 mm) and so on .

e. Spur Gear precision : Grade ⅴafter teeth surface grinding .

f. Cylindrical gear test : material UT , teeth MT after heat treatment , gear match test and so on .

3) Cylindrical gear Application

• Mining

• Metallurgy

• Power Generation

• Cement Plant

• Port Machinery

4) Spur gear Related Names

|  |  |

|  |  |

|  |  |

If you are interested in our products and want to know more details, please leave a message here, and we will reply to you as soon as possible.

Tel: 0086-519-88100328

WhatsApp: +86-0086-519-88100328

Email: sales@baoxincz.com

No 1788, Huacheng Road, Jintan District, Changzhou City, Jiangsu Province, China

Changzhou Baoxin Metallurgy Equipment Manufacturing Co., Ltd. is a high-tech enterprise registered in Changzhou City of Jiangsu Province, which is mainly engaged in the design and manufacture of spare parts for metallurgy equipment, hoisting machinery, oil drilling rigs, and heavy decelerator boxes.